An in-ground pool transforms your backyard into a private resort, significantly boosting property value while creating a gathering place. Whether you envision elegant pool parties, morning lap swims, or simply a beautiful water feature that enhances your landscape, selecting the right pool type represents one of the most important decisions in the entire project.

Before breaking ground, you need to address several crucial steps. First, verify local zoning regulations and permit requirements, as Southern California municipalities maintain specific setback rules and safety codes.

Second, conduct a property survey to identify underground utilities and assess soil conditions.

Third, establish a realistic budget that accounts for construction, ongoing maintenance, and landscaping.

Finally, consider your long-term lifestyle goals and how the pool fits into your daily life.

Here at Mission Pools, we’ve helped thousands of homeowners to improve their backyard aesthetic with luxury pools. We’ll break down the types of in-ground pools and why you may go for one option over another, to help your decision-making.

If you’re new to pool ownership, understanding a few key factors quickly narrows your choices to the pool type that perfectly matches your situation.

Your budget naturally plays a significant role in determining which pool types are realistic options. Being clear about your comfortable investment range helps focus decision-making on pools that deliver the features you value without overextending financially.

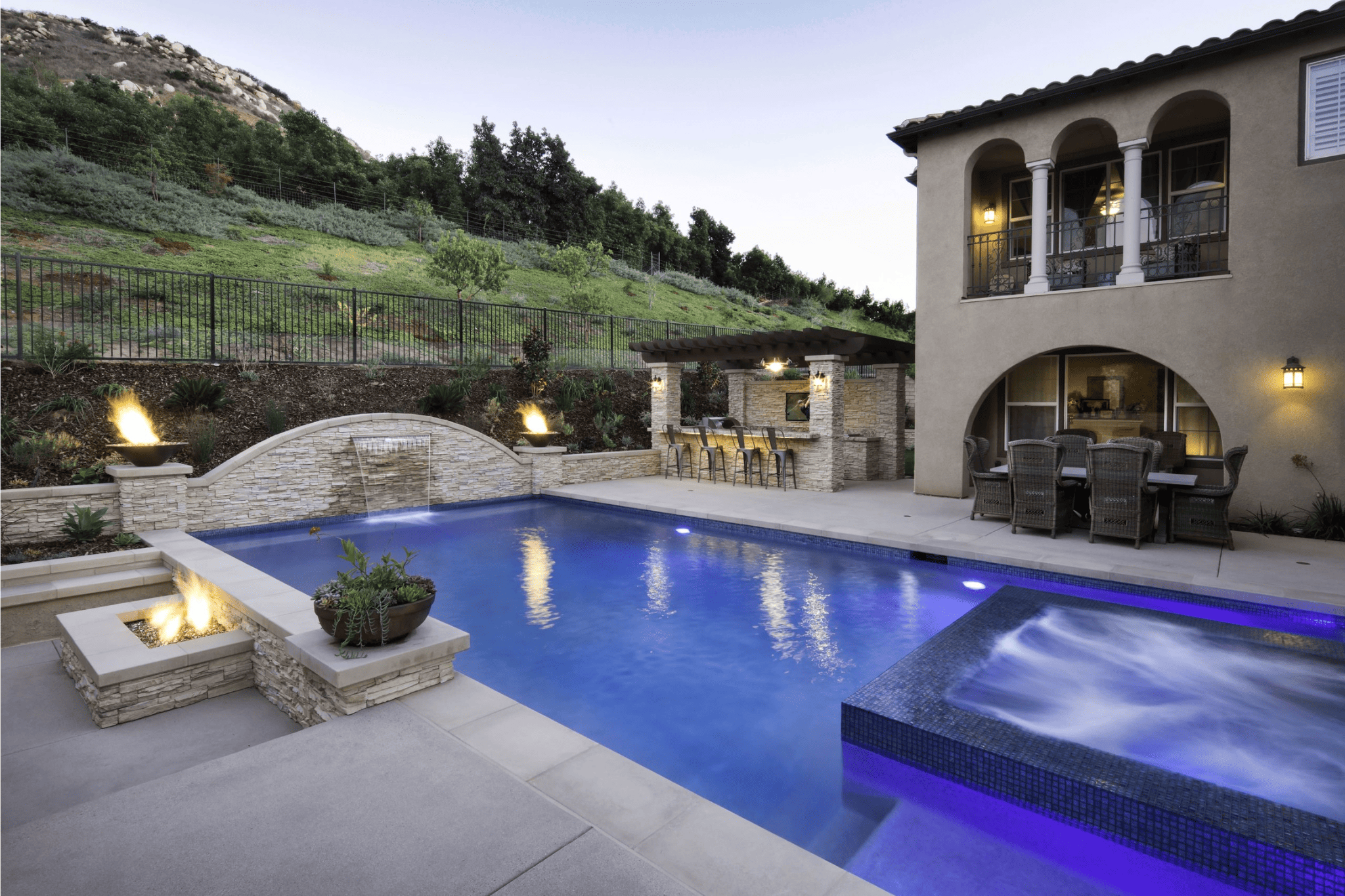

Home design style should influence your pool selection. Sleek modern homes pair beautifully with contemporary fiberglass shells or minimalist concrete designs, while Mediterranean architecture often calls for custom concrete pools with decorative tile work and organic shapes.

Consider your primary use case when evaluating pool types. Families with young children prioritize safety features like beach entries and shallow play areas, fitness enthusiasts need lap lane configurations, and homeowners focused on aesthetic appeal often invest in dramatic water features and lighting.

Property size and soil conditions can eliminate certain options or add unexpected costs. Compact urban lots might struggle to accommodate the equipment required for large concrete pours, while rocky soil or high water tables can significantly impact installation complexity across all pool types.

Southern California’s climate creates nearly ideal pool conditions with year-round usability and abundant sunshine. However, intense UV exposure, minimal rainfall, and occasional Santa Ana winds should influence material selection toward options that withstand sun damage, resist algae in warm water, and handle debris efficiently.

Concrete pools are constructed by spraying a mixture of concrete and sand over a steel rebar framework, creating a solid structure that can be shaped into virtually any configuration imaginable. The two primary methods, gunite and shotcrete, differ slightly in their mixing process but produce essentially identical results.

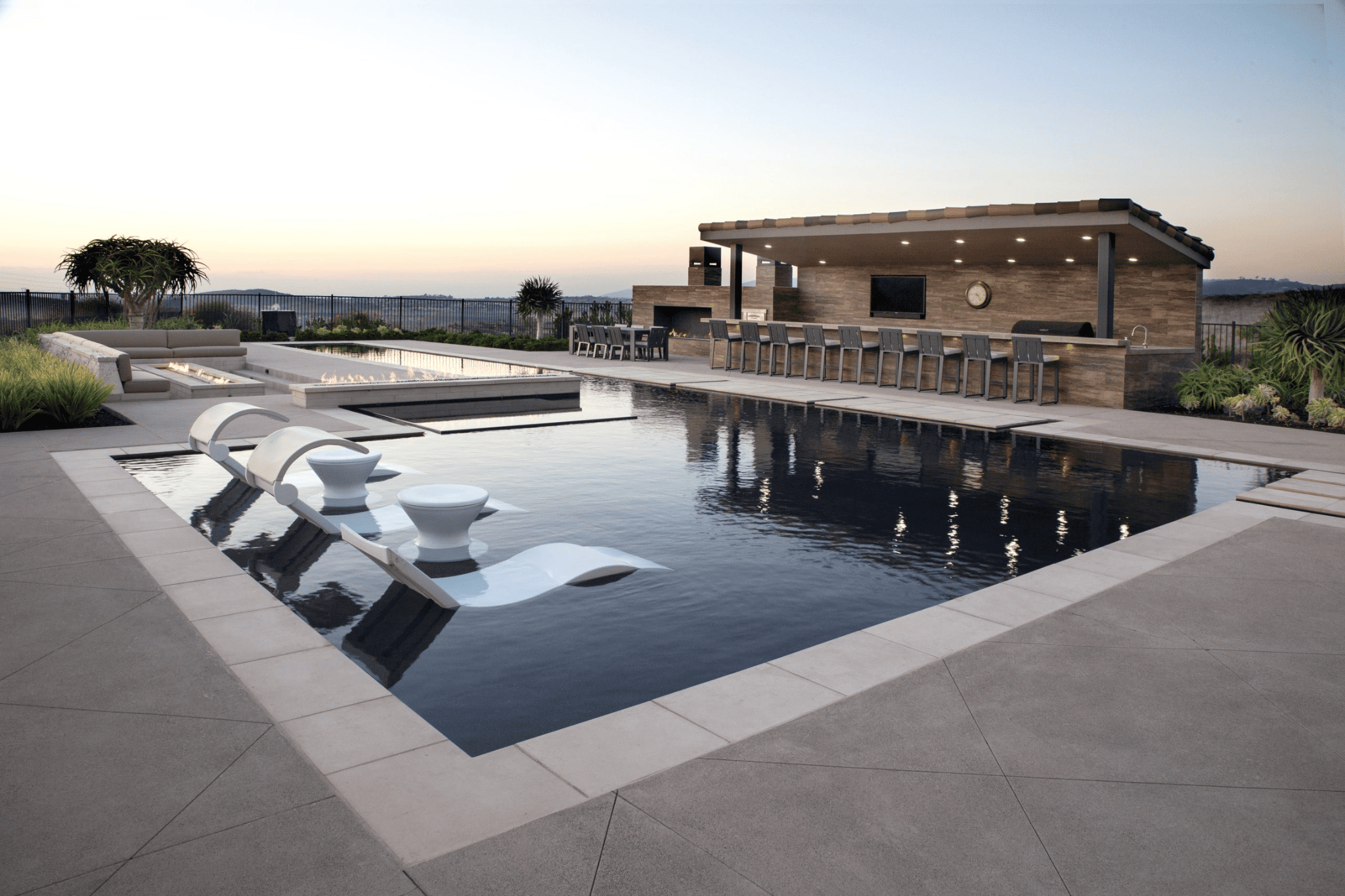

Concrete pools dominate the high-end market because they eliminate design compromises. If you can imagine it, skilled contractors can build it, making concrete the automatic choice for homeowners who refuse to settle for predetermined shapes or standard features.

The complete customization concrete pools offer simply cannot be matched by prefabricated options. Designers create exact shapes, depths, and configurations that perfectly complement your property’s unique characteristics. Want a shallow sun shelf transitioning to an eight-foot deep diving area? Need an irregular perimeter following your hillside lot’s natural contours? Concrete handles it easily.

Well-constructed concrete pools regularly last 50 years or more with proper maintenance, outliving the homes they’re attached to in many cases. The structural integrity of reinforced concrete withstands ground movement, temperature fluctuations, and decades of use without compromising safety.

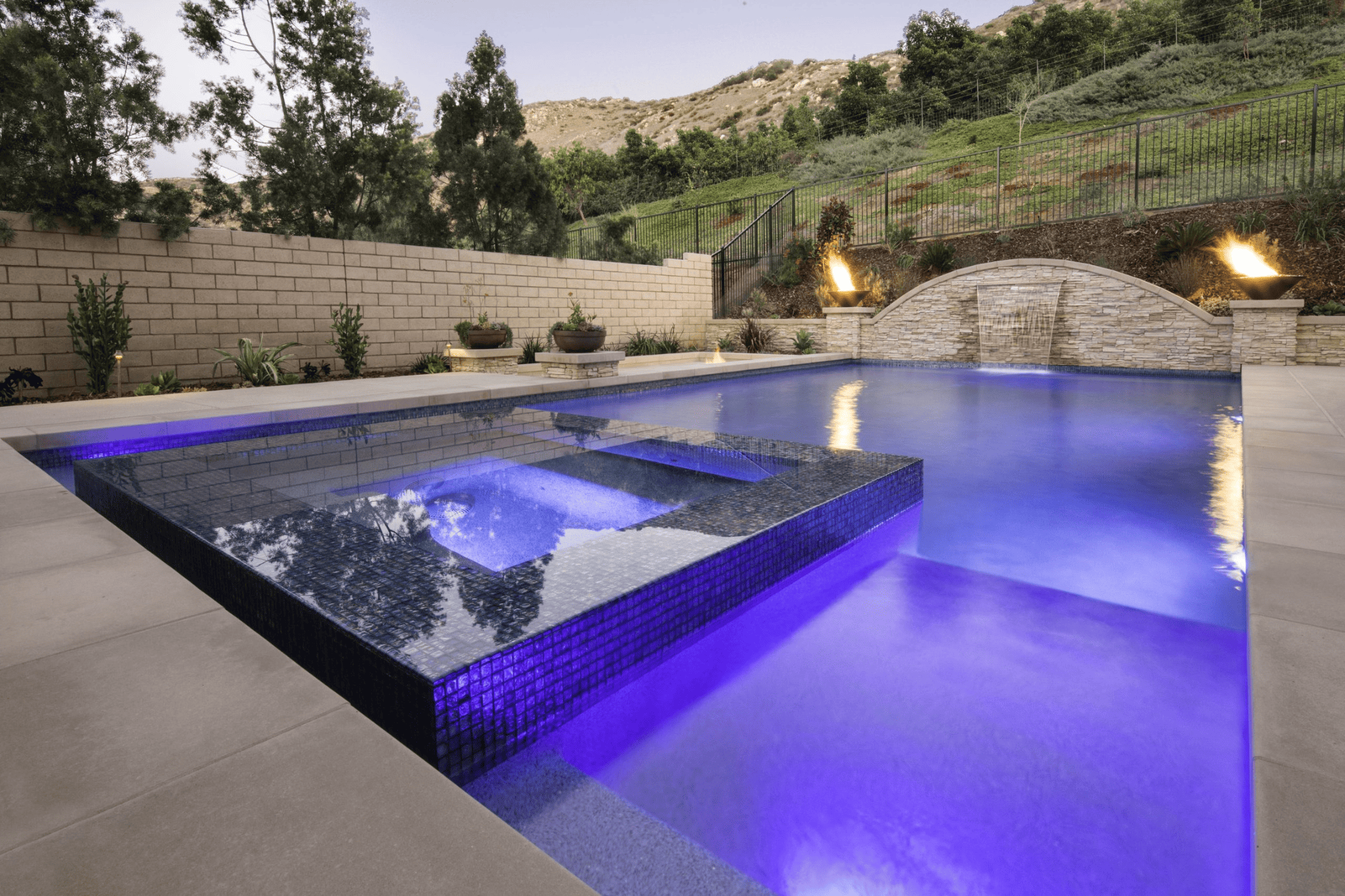

The range of finish options available far exceeds alternatives, from smooth traditional plaster to elegant Pebble Tec, stunning glass tile mosaics, and natural stone coping. These choices let homeowners achieve exactly the aesthetic they envision, whether modern minimalism, Mediterranean elegance, or tropical resort vibes.

Price represents the most significant barrier. Southern California installations typically start around $70,000 for basic designs and frequently exceed $150,000 for pools with custom features, integrated spas, dramatic water features, and premium finishes.

Installation timelines require patience, as concrete pools typically take 2-4 months from excavation to completion. This reflects multiple stages involved in steel placement, concrete application, plumbing and electrical work, curing time, and finish application.

Concrete pools require resurfacing every 10-15 years depending on the finish type, typically costing $5,000-$15,000 or more depending on pool size. The porous nature of concrete finishes means they can harbor algae more readily than smoother alternatives if chemical balance isn’t maintained consistently.

Fiberglass pools arrive at your property as complete, pre-manufactured shells that are carefully lowered into a prepared excavation and backfilled into position. These one-piece structures are factory-molded from layers of fiberglass fabric saturated with resin, then finished with a smooth gelcoat surface in various colors.

Installation speed represents one of fiberglass pools’ most compelling advantages. Within 2-4 weeks from project start to finish you can be swimming, faster than the months required for concrete construction.

The smooth, non-porous gelcoat surface resists algae establishment far better than concrete alternatives. This translates directly into reduced chemical usage, less frequent brushing, and significantly easier routine maintenance throughout ownership.

The 2-4 week timeline beats concrete pools by months, letting you maximize California’s long swimming season.

Quality fiberglass shells typically last 25-30 years with manufacturers offering substantial structural warranties. The flexible nature of fiberglass allows it to handle minor ground movement without cracking, valuable in California where seismic activity creates challenges for rigid materials.

Limited size and shape options represent the primary compromise. While manufacturers offer numerous designs, you’re selecting from predetermined molds rather than creating a truly custom configuration. Maximum widths rarely exceed 16 feet due to transportation restrictions.

Fiberglass shells are harder to repair if damaged. Surface scratches or gelcoat discoloration require specialized repair techniques that often show visible differences from the original finish.

Transport restrictions limit shell sizes based on road width, overhead clearances, and turning radius requirements for delivery trucks. Urban properties with narrow streets or rural locations requiring passage under low bridges may find preferred models cannot be delivered.

Vinyl liner pools use a flexible vinyl membrane installed over a structural frame made from steel, polymer, or aluminum panels. The liner typically measures 20-30 mil thickness and comes in numerous patterns and colors.

This modular construction keeps initial costs substantially lower than concrete alternatives, making in-ground pools accessible to homeowners who couldn’t otherwise afford permanent installations.

Lowest upfront cost makes vinyl attractive for budget-conscious homeowners. Southern California installations typically range from $40,000-$70,000, representing meaningful savings that can be redirected toward landscaping or patio upgrades.

The smooth texture feels comfortable and doesn’t harbor algae as readily as concrete finishes. Installation typically completes within 4-8 weeks, faster than concrete but slower than fiberglass.

The vinyl liner needs replacement every 7-10 years depending on sun exposure and chemical balance. This recurring expense, typically $3,000-$5,000 or more, represents an ongoing cost obligation throughout the pool’s lifetime.

Vinyl liners are easily punctured by sharp objects, pet claws, and rough play. While patch kits can repair small tears, larger damage often necessitates complete liner replacement well before the expected lifespan.

Vinyl pools are not ideal for high-end homes or luxury markets where they’re perceived as budget alternatives. In Southern California’s competitive real estate markets, particularly premium areas, vinyl pools may actually harm resale prospects.

Precast concrete pools occupy a middle ground between fully custom poured concrete and standardized fiberglass shells. Manufacturers create modular concrete panels in controlled factory environments, then transport and assemble them on-site.

This approach offers some customization possibilities while delivering faster installation than traditional concrete construction. Mid-range pricing between vinyl and fully custom concrete makes precast worth considering for homeowners seeking concrete’s durability without the extended timeline.

Repurposed shipping containers transformed into pools represent an innovative, sustainable option. The sustainable and compact nature suits urban properties with minimal space, but container pools remain uncommon in luxury settings where their industrial aesthetic conflicts with expectations for high-end outdoor living spaces.

| Pool Type | Average Cost | Installation Time |

| Concrete | $70,000–$150,000+ | 4–6 months |

| Fiberglass | $50,000–$100,000 | 2–4 weeks |

| Vinyl | $40,000–$70,000 | 4–8 weeks |

Your specific property characteristics and customization choices will significantly affect final pricing. Difficult site access, poor soil conditions, extensive deck work, and premium finishes can push costs substantially above these ranges. Sometimes you will have pool finance options which can reduce the initial investment, but that depends on the company.

Concrete pools demand high ongoing maintenance including regular brushing and careful chemical monitoring. However, their exceptional lifespan of 50+ years means the per-year cost over the pool’s entire life can compare favorably to alternatives.

Fiberglass pools require minimal routine maintenance beyond basic chemical testing, dramatically reducing time and money spent on weekly upkeep. Their moderate lifespan of 25-30 years means homeowners might replace one fiberglass pool during their residence.

Vinyl pools fall into a middle maintenance category, but their frequent liner replacement needs create recurring expenses. When calculating true lifetime costs, vinyl’s initial savings often disappear once you account for three or four liner replacements.

Luxury pools boost resale value in Southern California markets where outdoor living represents a fundamental lifestyle expectation. High-quality concrete pools in desirable areas often return 50-70% of their initial investment through increased home value.

Southern California’s climate creates year-round pool use potential that maximizes your investment. Heat and sun exposure favor low-maintenance materials like fiberglass that resist UV damage and maintain their finish without frequent resurfacing. Concrete pools with quality finishes also perform excellently under these conditions.

Concrete offers full design flexibility that lets architects create pools perfectly integrated with your home’s architecture. Fiberglass offers sleek, modern shapes that complement contemporary architecture beautifully. Vinyl remains more common in mid-range properties where budget constraints prevent concrete installation.

Concrete pools provide the highest-end appearance expected in luxury real estate markets throughout Southern California. Properties in areas like Orange County, Malibu, La Jolla, and Pasadena demand concrete pools that match the sophistication of the residences they accompany.

Concrete pools easily incorporate attached spas with spillover features and beach entries that integrate seamlessly into custom pool designs. Some fiberglass shells include these popular features as part of their molded design, though options remain limited to whatever configurations manufacturers offer.

Concrete pools accommodate dramatic additions effortlessly since designers plan for necessary plumbing, electrical service, and structural support during initial construction. Fiberglass pools can incorporate these features but require more careful planning since the shell arrives complete.

Modern controllers manage filtration schedules, heating, cleaning systems, and lighting through intuitive smartphone apps across all pool types. Integrating with smart home systems creates seamless control where pool functions respond to voice commands and adjust automatically based on weather conditions.

Pebble Tec, plaster, and tile represent the three primary concrete pool finish categories. Traditional white plaster creates a classic appearance at the lowest finish cost. Pebble Tec and similar aggregate finishes cost more initially but last longer and resist staining better. Tile provides the ultimate luxury finish with stunning visual effects and essentially permanent durability.

Built-in color and texture options come standard with fiberglass shells, with manufacturers offering various gelcoat colors from traditional blues to modern grays and even dark finishes. Buyers remain limited to manufacturer’s selection rather than having unlimited choice.

Vinyl liners provide the least customizable finish option, with most selections limited to various shades of blue or simple tile pattern prints. The visible liner track at the waterline creates an appearance that experienced observers immediately recognize as budget-conscious.

Prioritize design? Custom concrete pools deliver unlimited creative freedom to realize your exact vision. Want fast installation and low upkeep? Fiberglass pools excel at delivering hassle-free ownership with minimal ongoing maintenance. Tight budget but still want in-ground? Vinyl liner pools make in-ground pool ownership accessible at the lowest initial investment.

Benefits of choosing a luxury pool contractor extend far beyond construction quality. Experienced contractors anticipate problems before they occur, navigate permitting efficiently, and deliver finished projects that exceed expectations.

Expert design consultation proves invaluable when dealing with sloped lots, poor soil conditions, or tight access. Permits, soil conditions, and regional codes throughout Southern California vary significantly between jurisdictions and require intimate local knowledge to navigate efficiently.

Mission Pools has served Southern California since 1960, making us one of the region’s oldest and most respected luxury pool builders with unmatched expertise in custom concrete pool design and construction. We specialize in custom concrete pools that push design boundaries while maintaining the structural integrity and finish quality that defines truly luxurious outdoor living spaces.

Whether you envision an infinity-edge pool overlooking the Pacific, a resort-style oasis with integrated spa and dramatic water features, or a sophisticated lap pool that complements your modern architecture, our design team brings your vision to life with craftsmanship that stands the test of time.

Contact Mission Pools today for a free design consultation where we’ll discuss your goals, evaluate your property, and present options tailored specifically to your needs. Our service area covers Southern California including San Diego, Orange County, and Riverside County.

The best type depends on your budget, timeline, and design goals. Concrete pools offer full customization and luxury finishes but require the highest investment at $70,000-$150,000+ and take 2-4 months to install. Fiberglass pools install quickly in 2-4 weeks and require minimal maintenance, making them ideal for homeowners prioritizing convenience. Vinyl pools cost less upfront at $40,000-$70,000 but need liner replacement every 7-10 years and don’t match the durability or appearance of concrete or fiberglass alternatives.

Installation timelines vary significantly by pool type. Concrete pools require 2-4 months from excavation to completion due to multiple stages involved in construction. Fiberglass pools install remarkably quickly at just 2-4 weeks since the pre-manufactured shell arrives complete. Vinyl pools fall in between at 4-8 weeks depending on site conditions.

Concrete pools dramatically outlast alternatives, regularly exceeding 50 years of service life with proper maintenance and periodic resurfacing every 10-15 years. Fiberglass pools provide solid 25-30 year lifespans with minimal maintenance requirements. Vinyl liner pools last indefinitely in terms of structure but require liner replacement every 7-10 years.

Fiberglass pools win the maintenance ease competition decisively. Their smooth, non-porous gelcoat surface naturally resists algae establishment and requires fewer chemicals and less frequent cleaning. Concrete pools demand more attention including regular brushing to prevent algae colonization. Vinyl pools fall somewhere in between.

For Southern California’s sunny, dry climate with year-round swimming potential, both concrete and fiberglass pools excel. Fiberglass resists UV damage exceptionally well, installs quickly, and requires minimal maintenance. Concrete pools offer the full customization and luxury finishes expected in high-end Southern California properties. The choice depends primarily on whether you prioritize complete design freedom and maximum luxury (concrete) or quick installation with minimal ongoing maintenance (fiberglass).

You know . . . you just do not wake up one day and decide you can be someone’s partner in business. Strong relationships take...

Southern California is known for a lifestyle second to none. Our area that started out as an arid desert has now become a land of...

Yesterday was an example of why my brother and I enjoy this business so much. Contracting is all about solving problems…problem/solution management.