Your inground swimming pool construction budget is tied to your site, not a generic price list.

Access width, soil conditions, slope, and underground utilities shape excavation, steel placement, plumbing runs, and inspection steps. Those realities also influence where the pool can sit and how the deck and equipment pad fit.

As the plan comes together, design choices start moving the number in predictable ways.

A clean rectangle with a standard finish keeps complexity low, while custom curves, deeper profiles, premium tile, and automation increase labor and materials costs.

At Mission Pools, we connect each choice to how you will use the space.

In-ground swimming pool construction builds a permanent pool below grade, engineered into your property. It combines excavation, a structural shell, plumbing and electrical systems, and finishes that seal the surface and define the look.

Above-ground pools can be easier to set up, though they rarely integrate as well.

With residential inground swimming pools, the build also accounts for decks, drainage, equipment placement, and safe access, so inground pool installation supports daily use and long-term value.

Code and standards treat pools as regulated systems, not decorative features. As outlined in the ICC International Swimming Pool and Spa Code, requirements tie into electrical and plumbing compliance, so swimming pool design and construction choices should be established early for custom inground swimming pools.

A realistic budget range keeps your planning grounded, while still leaving room for choices that make the pool feel personal.

Even when two designs share the same footprint, inground swimming pool construction can price out differently because site conditions change the scope of excavation, structure, and finishing work.

That is where materials enter the conversation, since they influence both the build approach and long-term ownership.

As reported by HomeAdvisor, typical costs vary by vinyl, fiberglass, and concrete, which helps you compare options. To keep the budget practical, it helps to consider common pool financing options early, so you can translate the total project cost into a monthly plan that fits your household.

Your budget often builds in layers:

This order keeps the scope clear as decisions expand.

Basic entry-level builds keep inground swimming pool construction simple.

You will usually see a clean shape, standard depths, and a short feature list, which keeps planning and labor more predictable.

Because the scope stays tight, the focus shifts to function. Your backyard inground swimming pool typically includes excavation, the shell, basic plumbing and electrical, standard coping, a starter deck area, and startup, so you can swim comfortably without paying for premium automation or complex design upgrades.

Mid-range projects are where your pool stops feeling “standard” and starts feeling designed for how you live.

The structure stays practical, while finishes and layout choices add comfort, style, and usability.

That personalization often shows up through upgrades like:

This is also where many custom inground swimming pools hit a strong balance, since the upgrades improve day-to-day use without turning the scope into a full luxury build.

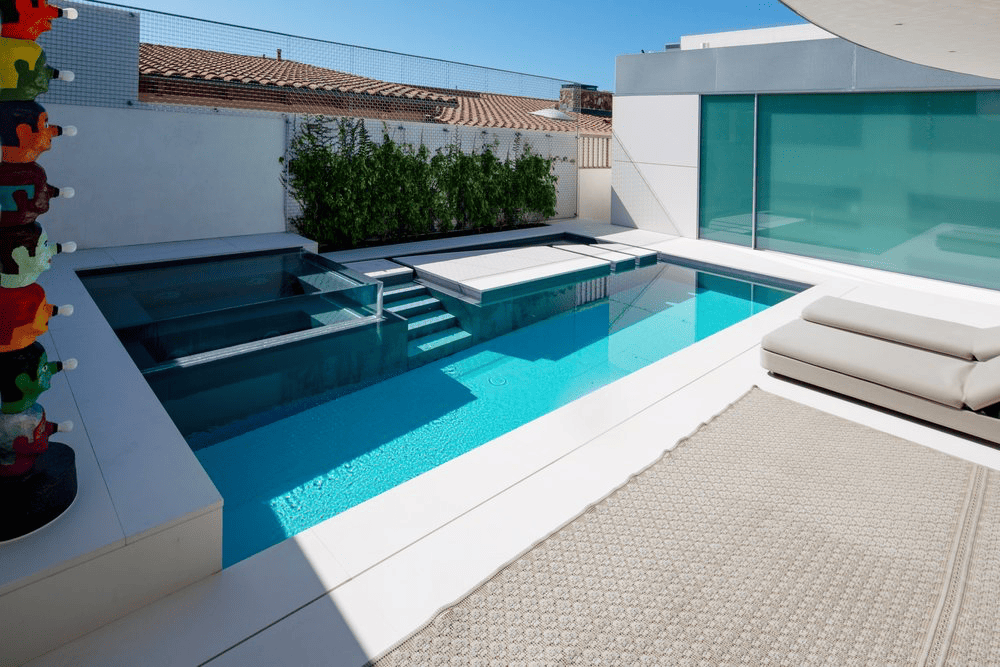

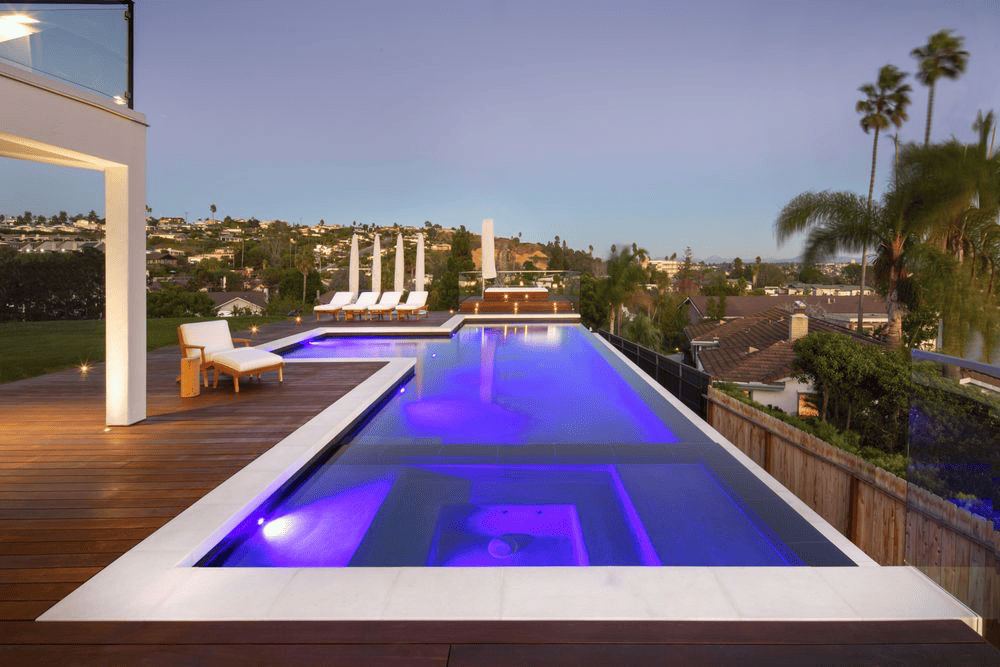

Luxury builds lean into custom engineering, premium materials, and showpiece features.

This is where luxury inground pool design often includes integrated spas, raised bond beams, complex water features, fire elements, high-end tile, advanced automation, and dramatic edges.

If you are drawn to clean sightlines and a “water meets horizon” look, negative-edge pool design inspiration helps you see how edge detailing changes the structure, hydraulics, and visual impact.

Costs rise because the build requires tighter tolerances, more trade coordination, longer finish timelines, and deeper expertise to make the pool look effortless while performing flawlessly.

Pricing usually comes down to scope and site realities. Size, depth, and materials set the baseline, while access, slope, and soil can significantly change excavation effort.

Local requirements also shape the plan.

The City of Redding residential pool permit brochure notes that permits are required for in-ground pools and any related plumbing or electrical work, and outlines setback and barrier requirements that can influence layout and timing.

Pool size sets the baseline because more square footage means more excavation, structural work, and finish surfaces.

As the footprint grows, plumbing runs and equipment sizing often expand too, which can push your inground pool construction cost even when features stay simple.

Shape adds complexity in a different way. Rectangles are efficient to form and finish, while freeform curves and custom geometry increase layout, forming, and detailing time during in-ground pool installation.

If you are weighing alternatives to the standard rectangular pool shape, circular pool design ideas can help you picture how curves change circulation, seating zones, and deck lines before you commit to a footprint.

The This Old House inground pool cost guide explains that costs commonly scale with pool size and vary with shape and features.

Depth drives excavation and structure.

A shallow play zone, a deeper swim zone, and multi-level transitions can improve usability, yet they increase structural planning and build complexity.

The more the pool changes elevation, the more the engineering and layout decisions matter.

This is also where safety planning becomes part of the design conversation, not a last-minute add-on.

Most inground swimming pool construction uses concrete, fiberglass, or vinyl. Material choice affects shape freedom, surface feel, and how you maintain the pool over time.

The NerdWallet guide on inground pool costs notes that concrete or gunite is typically more expensive but lasts longer, while vinyl and fiberglass can lower upfront costs and speed installation. Concrete swimming pool construction fits unique layouts and integrated features.

| Pool Type | Customization & Design | Installation Time | Cost Considerations | Durability & Maintenance | Best For |

| Concrete (Gunite) | Highest flexibility in size, shape, depth, benches, and integrated features | Longer build cycle due to on-site forming, steel, and finishing | Higher upfront investment tied to labor, structure, and finish selections | Very durable, surface care and refinishing cycles can be more involved over time | Luxury inground pool design, fully custom inground swimming pools |

| Fiberglass | Limited to available shell shapes and sizes, clean molded steps are common | Often faster once excavation and base prep are ready | Predictable pricing band, fewer custom structural add-ons | Smooth surface, typically less brushing, resistant to algae attachment | Quick inground pool installation, easy upkeep |

| Vinyl Liner | Moderate flexibility, best for classic shapes and standard depths | Often quicker than concrete, site conditions still affect the schedule | Lower entry cost, liner replacement adds lifecycle expense | Liner can require periodic replacement, moderate durability | Budget-conscious residential inground swimming pools |

Design planning is about protecting the experience you want.

A pool can look stunning on paper and still feel awkward in real life if circulation paths, sun exposure, privacy lines, and daily use patterns are not designed into the layout. Our goal is to align aesthetics with how you live, so the pool feels natural in your yard and your routine.

Your yard sets the build envelope for a backyard inground swimming pool, so placement starts with constraints like setbacks, access, slope, drainage, and utilities.

Once those are clear, design becomes about everyday use.

Style decisions affect cost by influencing materials and labor.

A modern look might emphasize clean lines, large-format tile, and crisp coping. A resort-style look might layer textures, waterline tile, and integrated landscaping.

If you want a luxury inground pool design, we can design a cohesive package that feels intentional, not like a list of upgrades bolted onto a basic plan.

Features shape comfort, and they also shape scope. This is where swimming pool design and construction becomes personal, because each add-on changes how you use the space day to day.

Timelines vary with permits, engineering, weather, and site conditions across each city.

Design and planning turn ideas into build-ready documents, so the scope is clear before any digging starts. You lock in the layout, elevations, equipment placement, and finishes, while engineering confirms the structure and the plumbing and electrical plans.

Permitting runs alongside those steps, which protects the schedule once crews mobilize. Safety fits here, too, because barrier and gate details affect access points and deck circulation.

The California Swimming Pool Safety Act requirements outline compliant enclosures and expectations for self-closing, self-latching gates, so designing with these rules early prevents layout changes later.

This is where the yard transforms.

Excavation is performed, steel reinforcement is installed where applicable, and the pool shell is constructed.

Site access, soil behavior, and weather can influence how smoothly this phase moves.

For concrete swimming pool construction, the structural work is a major part of the schedule because the build is formed on-site and built.

Finishing is where the pool becomes usable and polished. Tile and coping lock in the visual line, the interior finish seals the surface, and decking completes how you move around the water.

Equipment gets connected and tested, inspections get cleared, and startup follows with water balancing and a walkthrough of the controls.

At handoff, everything should run cleanly, look intentional, and meet safety requirements.

A pool is a structure, a water system, and a safety environment all at once.

Poor construction can create issues that manifest later as leaks, cracking, drainage problems, equipment failures, and premature surface wear. Professional builders reduce risk by managing engineering, quality control, and trade coordination in a disciplined way.

Safety matters too. The CDC reports drowning remains a serious public health issue, and residential pool safety planning is a key part of responsible ownership.

When you work with experienced builders, your residential inground swimming pool plan also fits your lifestyle, so the design supports real use rather than just curb appeal.

We’ve built pools in Southern California since 1960, and that experience keeps your project practical while still letting the design feel personal. At Mission Pools, we guide the decisions that affect structure, finishes, and long-term upkeep, so your pool performs as well as it looks.

If you want a better sense of who we are and how we build, take a look at how we got started and what we stand for.

Already have a pool that needs a refresh? Our pool remodeling services for older pools show upgrade paths that improve comfort and appearance. For higher-use projects, explore our commercial swimming pool construction expertise.

When you want to talk about design and pricing tied to your yard, use our pool consultation contact page.

Inground swimming pool construction goes smoother when your plan answers the real questions early: what fits your property, what matches your lifestyle, and what level of finish you want to maintain long term.

Start with the fundamentals, size, depth, materials, and site conditions, because those choices set the structure and schedule.

After that, features can earn their place by improving how you swim, lounge, and host, instead of inflating scope.

If you want clarity on design, timeline, and a true inground pool construction cost range for your yard, contact us today and we’ll help you shape a build plan you can feel good about.

A realistic inground pool construction cost range depends on your pool type, yard access, engineering needs, and the features you want to live with long term. National cost guides show wide ranges by material, with concrete often higher than vinyl, and fiberglass often in the middle.

The build timeline depends on design complexity and local permitting. Some California cities note permit timelines that can take multiple months, which can influence the overall schedule even before excavation starts.

Concrete swimming pool construction is often worth it if you want maximum customization, a fully tailored shape, and flexibility in premium finishes. It may require more ongoing surface care over time than other pool types, so we weigh your design goals against your ownership expectations.

California has pool safety requirements for barriers and gates, and local permitting often requires plans that comply with those rules. Building code references for pool barriers outline enclosure and gate characteristics that influence layout and access points.

Start with how you plan to use the space: laps, lounging, kids’ play, entertaining, or a quiet retreat.

Your yard shape, setbacks, and sun exposure guide placement. Your feature list shapes usability. That approach keeps your backyard inground swimming pool design practical and beautiful.

You know . . . you just do not wake up one day and decide you can be someone’s partner in business. Strong relationships take...

Southern California is known for a lifestyle second to none. Our area that started out as an arid desert has now become a land of...

Yesterday was an example of why my brother and I enjoy this business so much. Contracting is all about solving problems…problem/solution management.