Concrete swimming pool construction forms a reinforced shell on site, so the pool fits your yard rather than forcing it into a template.

You can dial in depths, steps, edges, and sightlines with control.

In Southern California, tight access, slope, and buried utilities shape excavation, steel, plumbing, and inspections. That reality is why Mission Pools has built with a process mindset since 1960, keeping custom work organized and measurable.

Here, you will see how design freedom connects to concrete pool durability, finish options, realistic timelines, and the cost levers that move the number. Clarity stays.

Concrete swimming pool construction uses reinforced concrete and steel to form a shell that holds water, resists soil pressure, and stays stable over time.

Because it is built on site, the shell can match your yard’s footprint and depth profile with precision.

You will hear shotcrete and gunite during planning; these terms refer to how the mix is delivered and applied at the nozzle. The ACI 506R shotcrete guide preview outlines wet-mix and dry-mix methods and highlights placement and quality control.

Compared with fiberglass or vinyl, concrete often fits best when you want custom geometry, deeper transitions, or details that need an engineered shell. That is why many custom concrete swimming pools use concrete when design freedom matters most.

Concrete pools are premium, long-term investments that offer design flexibility, structural strength, and fully customized features.

Concrete pool design lets you match your home’s lines or soften them with freeform curves, while still controlling depth and circulation. So you can add a shallow lounging shelf, widen a swim lane, or shape steps that fit your natural entry path.

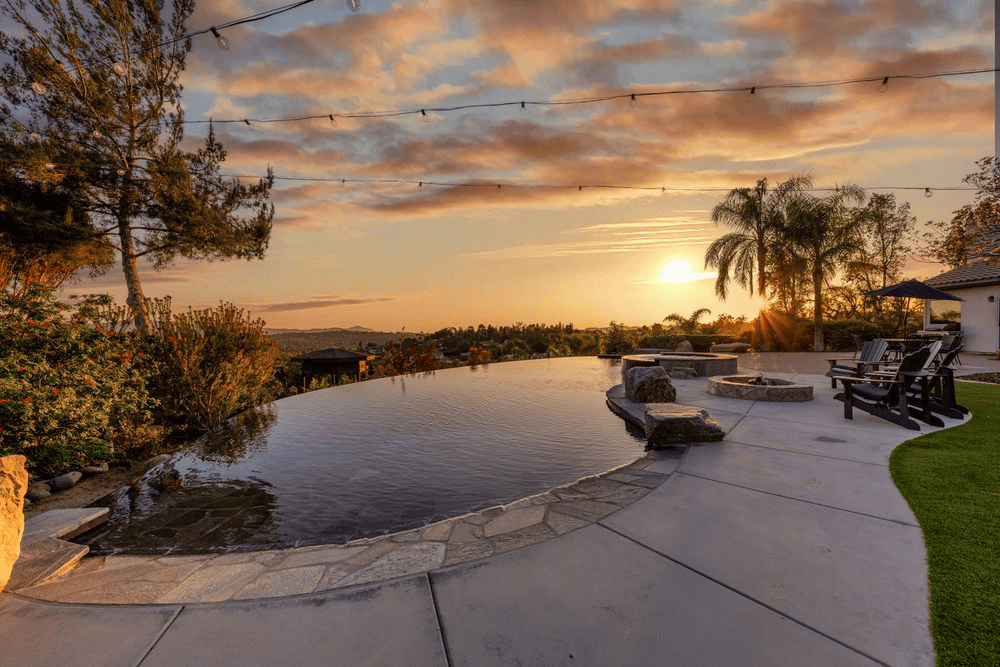

That freedom also supports luxury concrete swimming pools with infinity edges, perimeter overflows, and beach entries, because the shell is built to spec, and negative edge pool design inspiration helps you picture how those edge details change the look and the build precision.

The CDC Model Aquatic Health Code guidance notes design and construction considerations for aquatic venues, which reinforces the precision these features require.

This approach works for both residential and commercial concrete swimming pools.

Concrete lets you plan features as part of one engineered shell, so weight, plumbing runs, and waterproofing details stay coordinated.

That opens the door to upgrades that feel intentional, not tacked on later.

A correctly built concrete pool can serve for decades because its structure is engineered to withstand soil pressure, water load, and daily use. The long-term performance depends on steel placement, mix design, application quality, curing discipline, and waterproofing and finish choices.

In Southern California, durability discussions often include ground movement risk.

USGS notes the region has a very high earthquake risk and extensive fault systems, which is a reminder that structural planning matters on any long-lived outdoor build.

This is where experienced concrete pool builders set themselves apart. Great crews manage rebar placement, thickness consistency, and shotcrete application quality so the shell behaves like a unified structure, not a patchwork.

Your pool should feel like it belongs to your house, not like it landed there.

Concrete lets you wrap a pool around existing architecture, preserve a mature landscape, or fit a pool into a tight yard without sacrificing comfort.

Luxury homes reward details that look quiet but work hard. Concrete supports those choices, so tile lines stay crisp, coping sits flush, and lighting can layer the space after sunset.

Finish color also matters, because it shifts the water’s tone against your architecture and landscape. With this control, the pool can read resort, modern, or classic without fighting the house.

We plan layouts around outdoor living zones, sightlines, and guest flow. See how our process works on custom pool new builds.

Commercial concrete swimming pools take heavier daily use, so the design has less room for shortcuts. Hotels, resorts, fitness centers, and HOAs need predictable circulation, clear sightlines, and durable finishes that withstand constant traffic.

That is why design control matters. You can size the shell for the space, shape entries for safe flow, and plan equipment and drains for steady performance.

When codes and inspections are part of the job, concrete also makes it easier to build to spec, document the process, and deliver a pool that stays consistent season after season.

For larger properties, see our commercial work.

Surface finishes matter because they control two things you experience every day: how the pool looks, and how it feels.

The same concrete shell can read bright and modern or deep and resort-like, depending on finish color, texture, and how it catches light. Comfort shifts too, since some surfaces feel smoother underfoot while others add grip.

Concrete swimming pool construction timelines run longer because custom work relies on precise phases, inspections, and curing windows that protect long-term performance.

Your schedule also depends on design decisions and permit pacing, which can shift by city and site conditions. Most delays come via coordination, not the material itself. Many homeowners find it easier to plan once they have a clear modern swimming pool design in mind.

Key factors that influence build time include:

Pool barrier details can affect approvals, too, so align gates and latching hardware during design.

Concrete swimming pool construction costs run higher upfront because the shell is engineered and built on-site. You are paying for choices that fit your property and hold value.

Your total price usually shifts with:

The California Contractors State License Board notes pool contracts should list shape, dimensions, materials, and equipment, making cost drivers easier to spot. That keeps budgeting grounded.

If you want full control over shape, depth, and premium detailing, concrete is often the right match. If you need the fastest possible install with limited site disruption, other pool types can be worth a look, depending on your priorities.

Concrete tends to fit best when:

A consultation helps because your lot, soil conditions, and design goals shape the best path. You deserve answers that fit your property, not generic advice.

You are not only choosing a material, but you are also choosing the team that designs, plans, and builds a shell meant to perform for decades. That difference shows up in the details, how the steel is laid out, how the site is managed, and how clearly the process is communicated.

Mission Pools has built across Southern California since 1960, with a focus on craftsmanship, tight quality control, and a steady client experience, even when the design gets complex.

If you want a clearer sense of who we are and how we work, see our story and build philosophy.

Concrete swimming pool construction remains popular for luxury projects because it offers control that lasts. You can shape the pool around your home, choose features that match how you relax or entertain, and invest in a structure designed for long-term performance.

If you are weighing custom details, site constraints, or a property that needs commercial-grade durability, Mission Pools can help you make the trade-offs clear. We bring Southern California experience, a proven process, and craftsmanship that shows up in the finished lines.

When you are ready, schedule a consultation with Mission Pools so your plan reflects your yard, your goals, and a timeline you can trust.

Concrete swimming pool construction can last for decades when engineered and built correctly.

The shell usually outlives the interior finish, which may need refreshing sooner. Concrete pool durability depends on the steel, curing, waterproofing, and long-term maintenance.

Shotcrete and gunite describe how concrete is applied during concrete swimming pool construction, using wet-mix or dry-mix methods. For you, quality matters more than the label. Strong concrete pool builders focus on consistent placement, thickness control, and proper curing.

Commercial concrete swimming pools are common because concrete supports engineered structure, predictable circulation, and inspection-ready details under heavy use. Safety depends on compliant design, clear entries, durable surfaces, and properly planned equipment and suction systems.

Custom concrete swimming pools are easiest to upgrade during construction, when shaping and routing are open. Built-in steps, benches, tanning ledges, spas, lighting conduits, water features, and automation zones integrate cleanly and usually cost less than retrofits.

Concrete pool design and finishes work together to set water color, texture, and upkeep needs. Plaster leans classic, pebble feels more natural, quartz adds sparkle and wear, and tile sharpens luxury detailing. Choose based on comfort and maintenance tolerance.

You know . . . you just do not wake up one day and decide you can be someone’s partner in business. Strong relationships take...

Southern California is known for a lifestyle second to none. Our area that started out as an arid desert has now become a land of...

Yesterday was an example of why my brother and I enjoy this business so much. Contracting is all about solving problems…problem/solution management.